... for inspection of bars

High throughput rate and in operation worldwide! Detection of internal flaws is carried out with straight beam probes. For bar diameters greater than 30 mm, surface-near flaws are detected by angle beam probes. Key properties for the ECHOGRAPH-STPS bar inspection system are the high testing speed of up to 2 m/s and the simultaneous adjustment of the probe carriers producing short change-over times. The coupling of the ultrasound is achieved with guided water jets. The squirter probe holders for the water jet coupling allow test conditions comparable to immersion testing.

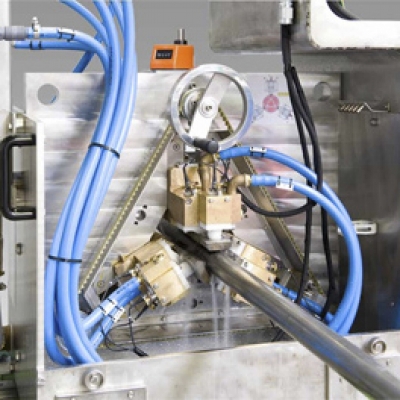

The inspection of the core region is carried out with three to five straight-beam probes. All probe holders are equally positioned around the bar circumference. The probe holders are mechanically protected by guiding skids usually made from hard-metal.

The skids are also responsible for stable coupling and testing conditions by guiding the probe holders along the bar surface. Unavoidable mechanical straightness tolerances of the bars are compensated for by the spring-loaded suspension of the probe holders.

See pdf document for more details.